So when I went to the shop tonight I thought to myself "I'm going to get the engine back in"...heh heh, yeah right. I started off by taking care a couple of details, and they snowballed and snowballed until all I had done was deal with details. The problem with details, is they take so freaking LONG!!!

First up, was mounting the coil. Should be simple, but the fuel-pump block off plate I'm using isn't flat. That left an angled gap right around the center of the photo below. Technically the hole doesn't matter, as the case is sealed by the gasket and plate...but should it fill with dirt and crap it could get into the case if I ever remove the plate:

Eventually I determined a grommet would take up the space and ensure that a good seal was made. With that, the coil project was done.

So up next, I trimmed engine tin to fit around the pump. Just a 'slight' bit of trimming required :P

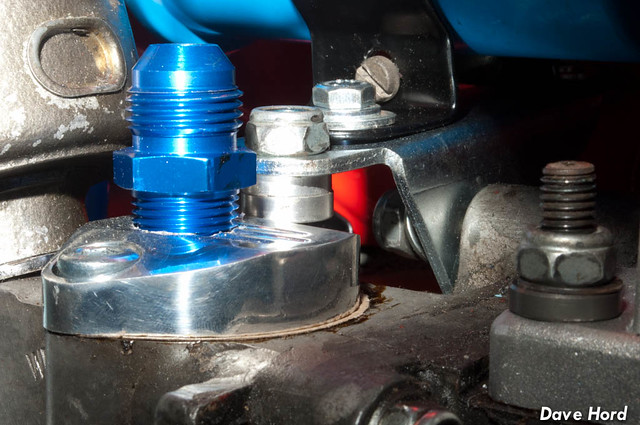

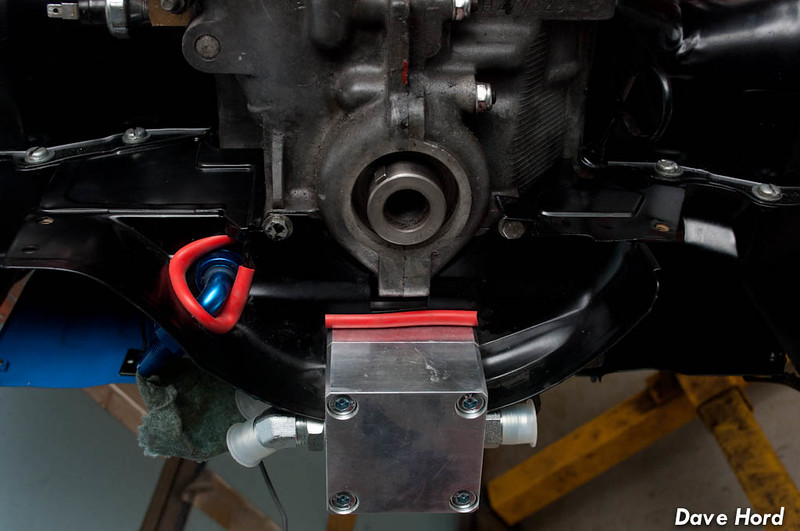

With that, I moved onto oil-tank cut-off valve. For whatever reason I had always planned on mounting this below the car, even though it would be incredibly annoying. I was having difficulty deciding where exactly to put it, so I asked Mark Huebbe to send me a photo of his. He's got a Beetle that he rallies in the Rally America series. As soon as I saw his placement it was like a bell went off. Why didn't I think of putting it

in the engine bay!?!

The valve, fittings and line are all very close or touching the tin. I am concerned about the potential heat factor and was thinking of possible solutions when it dawned on me. Vibrant Performance recently started carrying a new line of thermal products, so surely they would have something that would work? A quick phone call, even though it was 11:30pm, and I should have the required stuff coming by mail tomorrow. Gotta love good connections! Getting this to fit correctly required pulling off the pulley tin, yet again. I think that was probably the fifth time this evening alone. The worst part is I will still need to take the whole motor down to the point where I can take off the cylinder tins...in order to install a bolt for mounting the valve! I think I'm going to get lucky on the feed line, though, as I should be able to use the factory hole for the reverse lights to pass the oil line through from the tank to the valve. I'll confirm as soon as the engine gets remounted in the car...if not, another bulkhead will go in near the right-side carb.

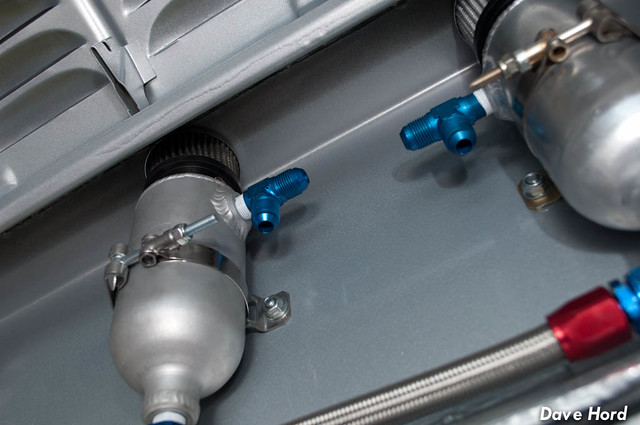

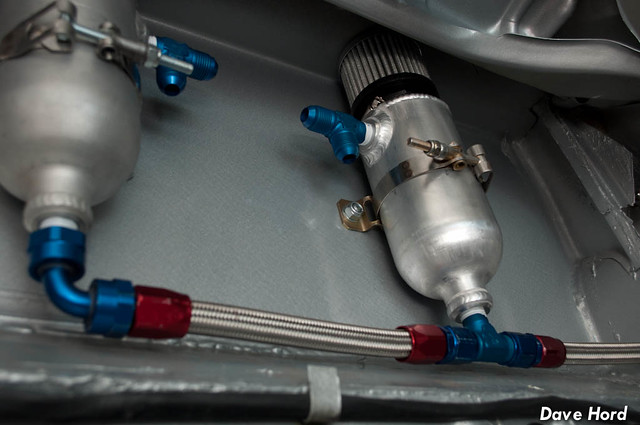

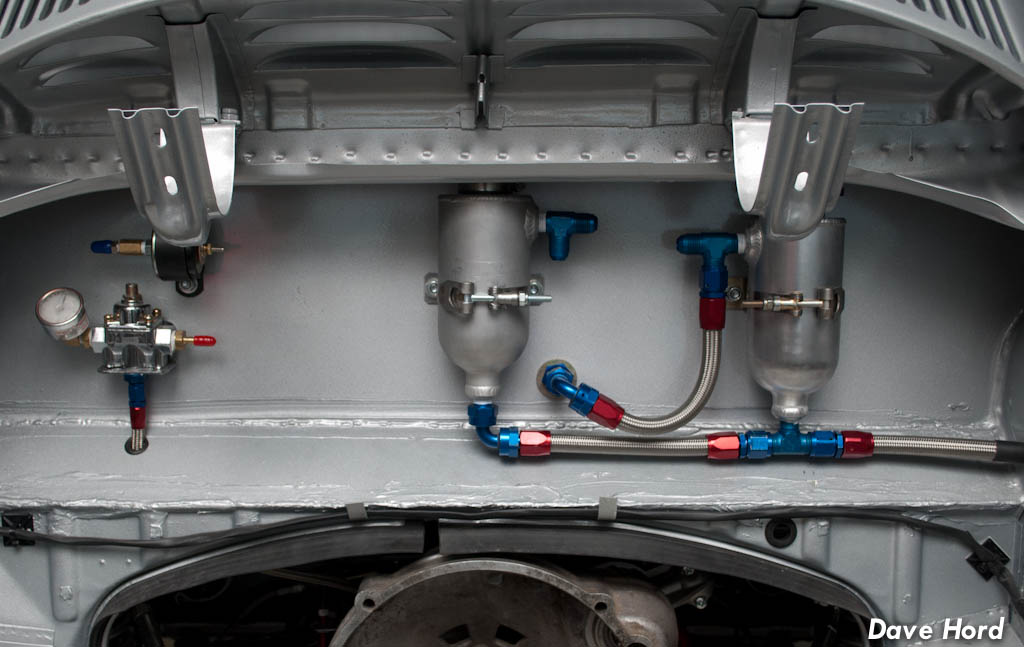

I then moved on to the breather system. I mounted up my second breather tank, removed all the lines and fittings from the first tank and then started reworking the whole system. Once I had it about halfway ready, I realized that I really needed to raise the one breather by about a half inch. With it already touching the top of my firewall, that wasn't going to be a simple task! Yet another detail to find a solution to...

With my new resized filter, everything fits exactly how I had imagined it in my head. Full sized filter on the right, shortened filter on the left.

Breather line for the tank was then added through the firewall, and now the system is ready for the engine install. I

should be able to disconnect the breathers easily with a stubby wrench, but I'll need to get the engine in to be sure. Add another item to the "check this" list!

Somewhere in the middle of all this I found myself sitting in the back of the car, probably tightening up a fitting or two, and realized that I could pop in a fuel filter and finish the fuel connections by the frame horn while I was there. Fuel system is now connected from the tank all the way to the regulator. No photos, it's just a filter ziptied to the speed sensor bracket!

It was about this point in the late evening that I realized I should begin tearing the motor back down. The garage, however, is a complete disaster with tools everywhere. I took a step back, thought about where to start tidying up, and then realized that would make a far better lunch-break project tomorrow during the work day. Besides, it was midnight and I still hadn't eaten dinner! I'll clean up the shop at lunch, and then be ready to start fresh at the end of the work day. Carbs off, motor in, oil-lines and breather lines completed. That's the goal for tomorrow...bonus points if I get the carbs back on :P

-Dave