I've got the proper studs coming from Porsche, but its going to be a week or two before they arrive. So, in the meantime, I'm working on other items that are needed to install the engine. Everything at this stage is taking twice as long as it should, because I'm needing to plan ahead. Everything I drill a hole for is permanent...so it needs to not only work with the engine as its but more importantly, it needs to work with the engine I build with IDF's and the Salzburg-style shroud.

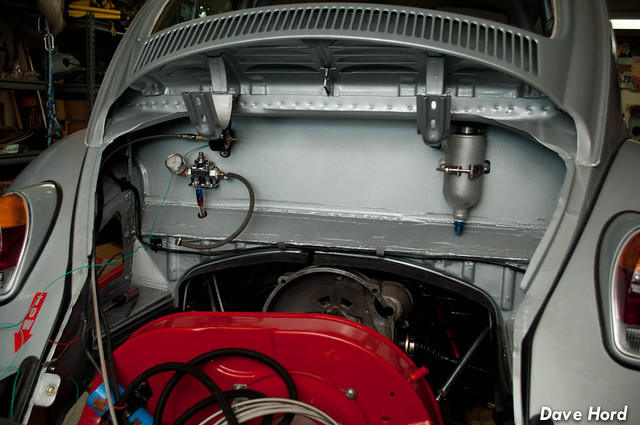

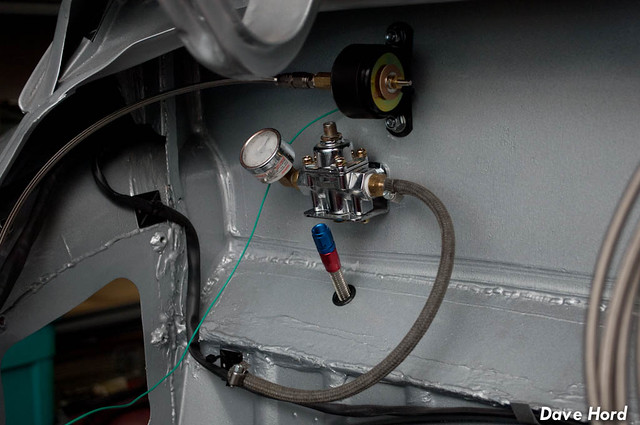

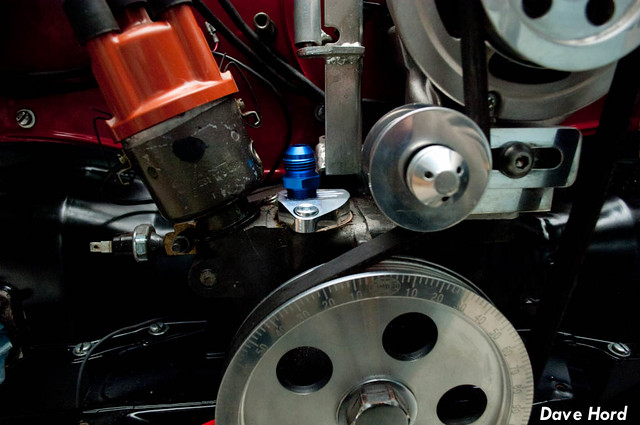

After a bunch of testing and measuring I finally determined the positioning for the crankcase breather, fuel pressure regulator and oil pressure sender.

Fuel pressure regulator (still need a fitting and a new gauge), and oil pressure sender. I won't be able to fit the Stewart-Warner sender in the same spot I had the Autometer sender as the body size is larger. I had done a remote sender on Connor's mustang, so I had all the -3AN fittings and lines on the shelf...so tucked this one out of the way with a left-over Coil bracket.

On the crankcase breather side, I decided to reuse the Moroso unit I had, instead of getting one of the rectangular box styles. For now I'll run both the valve covers and crankcase into this one unit, but when I hook up the dry sump system I think I'm going to mount a second one right beside it. I tend to forget about checking them for oil, and would rather not end up with a huge mess. The oil tank will be running a fairly high level of oil, so better to play it safe since I have the real-estate. I did realize that I own a 3/8NPT tap from modifying oil pumps, so made up a crankcase breather that I can use for now. I'm tempted to cut the threads deeper on the part, but the threads were cutting odd and I'm not really sure what type of aluminum it is...played it safe for now.

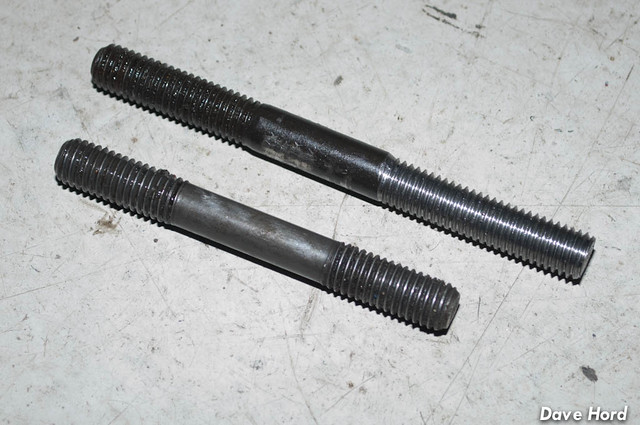

And lastly, the stud problem. With the proper Porsche studs coming, I figured I could mount the engine using bolts. The only reason I didn't, its the need to guide the engine in using just the input shaft on the transmission. So, some Audi engine bolts sacrificed their lives to become temporary engine studs. Cut threads aren't ideal, and leave a major stress riser right at the base of the last thread...so I'll swap these out as soon as I can. For the moment, however, they should work.

-Dave