Well, tis been a while. Worked on a few minor details over the weekend to try and adjust some issues. First up was grounding each of the temp senders to their own ground, I was getting some flaky readings or the feed-sensor dropping out, and the individual grounds seem to have solved that problem. The feed ground is a little messy, but I'll get in there again next weekend to make sure it's shrink-wrapped and permanent now that I've confirmed it's working.

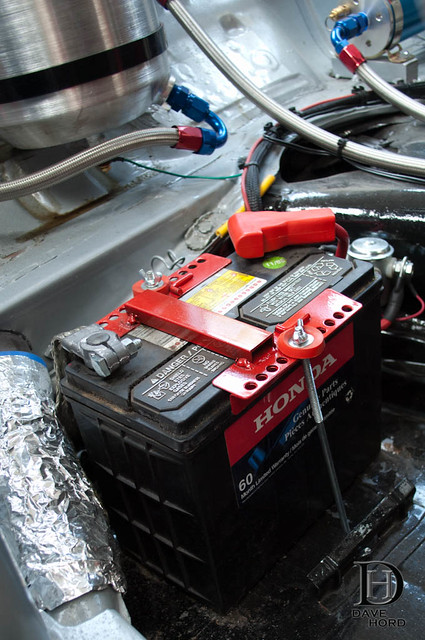

My F150 was stolen, and recovered. But in the process of the body shop replacing all the locks and repairing the doors, they messed up the interior light. Battery was discharged and charged enough over the course of the week that it was 100% dead. Wouldn't even hold a charge for an hour. As I'm not sure if the problem is 100% solved, I stole the deep-cycle optima from the Bug since they can be discharged flat a number of times without damage. I tossed in a Honda S2000 battery I have kicking around, and Ziptied it in for emergency use :P I figured I would get around to swapping it back soon, but then realized a RallyX is next weekend and I was more likely to show up at tech and

then remember I haven't swapped the batteries! A metal-on-metal mount was made for the Honda battery. It's ugly, but will pass tech!

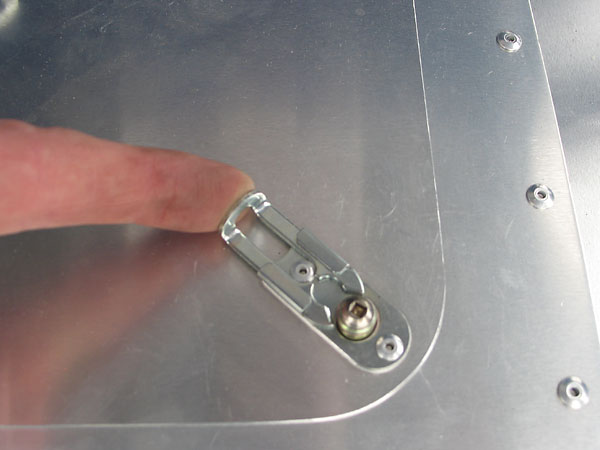

I've also been working on the cooling. The NACA duct flows too much air past the oil cooler, and running on the highway I can't actually get it up to 200deg running temperature. The thermostat I'm using to bypass the cooler still lets a small amount of oil pass through, and this is clearly a problem. A couple of tests with cardboard (blocking the duct) allows the car to come up to temperature...so a solution needs to be found! I honestly don't understand the aerodynamics of the duct well enough, but I know I need to keep the boundary layer intact as much as possible past the duct. This piece of lexan seems to be doing the job so far, might need to make it a little larger and/or adjust the shape.

Once I've got the shape/setup figured out I'll then swap the bolts out for Dzus 1500 fasteners. They will allow me to pull the panel at any point when the heat is getting to high for the fan to control. (Hot day at the track perhaps?).

I was up doing some gravel testing for the panel (high revs, long stints), which also highlighted another issue I need to deal with. The oil-level in the tank is quite sensitive, and it seems when I have it too high it will burp out of the dipstick tube under high-heat/revs! Will need to o-ring or otherwise seal the dipstick tube. Tough to see the top of the tank is all coated in oil.

...and, speaking of testing. Here's some proof that the car does indeed move under it's own power. I goofed on the front-mounted cam, and wasn't going to post a vid. But hey, if I keep waiting until I have a perfect one I will never post anything! :P

http://youtu.be/k7yPrwBifGw

-Dave