Next up, the crotch coolers. Toying with different ideas for quite a while.

In this pic, the crotch cooler hole was filled with a piece of carbon that was glued to a fiber plate of some sort. Not functional. The flaps were not available when the car was painted, but i've always wanted to have functional flaps with the carbon.

Tried to source the cooler flaps to gut/grind the hardware apart and try to fix them to a piece of carbon. Not available. Even the guys repoping the parts in South America didn't have those parts. So a OEM set were sandblasted clean and the thinking continued........

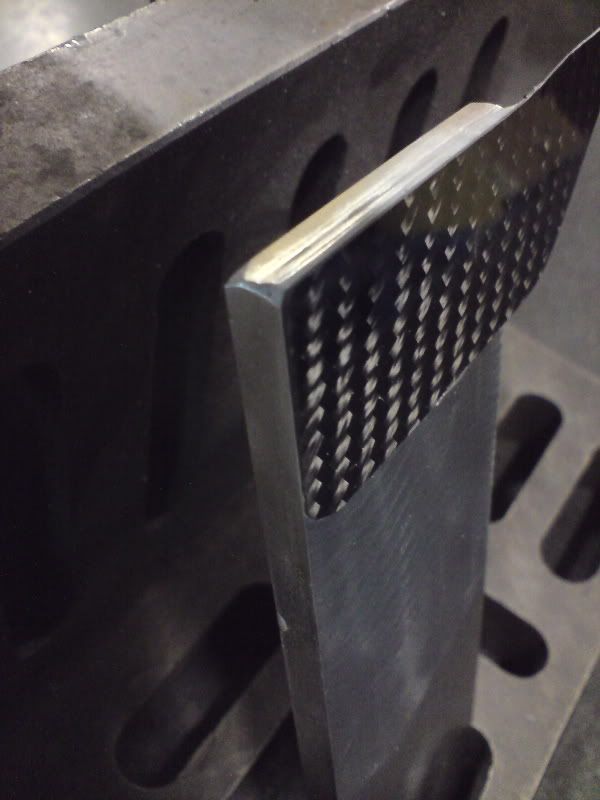

Cut apart a Carbon Joe panel for material. It was too thick so shaved/sanded down the 2 layers of fiberglass behind the carbon fiber. Was left with the one layer of carbon fiber, that was to my surprise, pretty flexible.

Now i needed to find an adhesive to get it to stick to metal really hard so i can sand it. Tried different quickset epoxies, instant adhesives, and some Loctite gel stuff. None worked well. Some had a weird reaction with the resin in the carbon, and others dried all rubbery. Gave JB Weld a try, and it was perfect.

A little oversize, and some extra gunk, to allow shaping:

Sanded:

Time to try it out for real.

It's now drying under the weight of some A2 steel, nice and heavy

I'll give it a couple days to get hard, before touching it. We'll see how this turns out.

Pete