Block ready to go back together with new seals, note tape on rod little ends to avoid the risk of scratching the bores on assembly.

All torqued and sealed up..

first piston going in...

all pistons in, you have to make sure they are all orientated correctly as well as positioning the piston ring gaps too

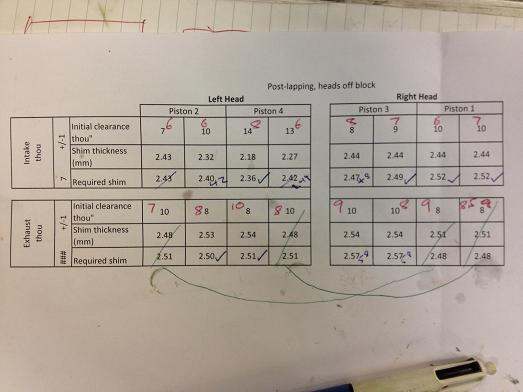

V4 STI cylinder heads stripped for refresh. All valves cleaned up, re-lapped in to the heads and then ready for first lash measurement. These heads use under-bucket solid shims which come in various different thicknesses and you change shims to get the correct clearances.

I knocked off any sharp edges in the combustion chamber to help avoid detonation, this can sometimes be an issue when fitting 2l heads on a 2.5 block due to the slight cylinder diameter mismatch

You can see one of the shims sitting on top of a valve.

Lots of measuring!

and measuring, then swapping shims

Ready to go on the engine!

ARP head studs fitted to give better head gasket clamping under boost

Back to a longblock! I had to fit the cambelt and re-check the valve clearances as the cam loading can change things. Luckily only one shim needed swapping after assembly.

V3/4 cam covers were cleaned up and treated to some VHT wrinkle paint, note one on left hadn't had any heat applied ot get the wrinkle effect started yet.

Coolant manifold needs modifying to clear the central 2.5l breather pipe.

Now I just have to decide what turbo and injectors to go with!