Let the case modifications begin! The Subarugears written directions are pretty poor, but his Youtube video on the modifications is quite complete. I'm a read/manual kinda guy, so I find it frustrating to have to pull up the YouTube video multiple times if I need to check something...but alas, I guess I'm old now :P

With the case ready, it was onto swapping out the pinion shaft, which is actually really really easy with the Subaru transmission.

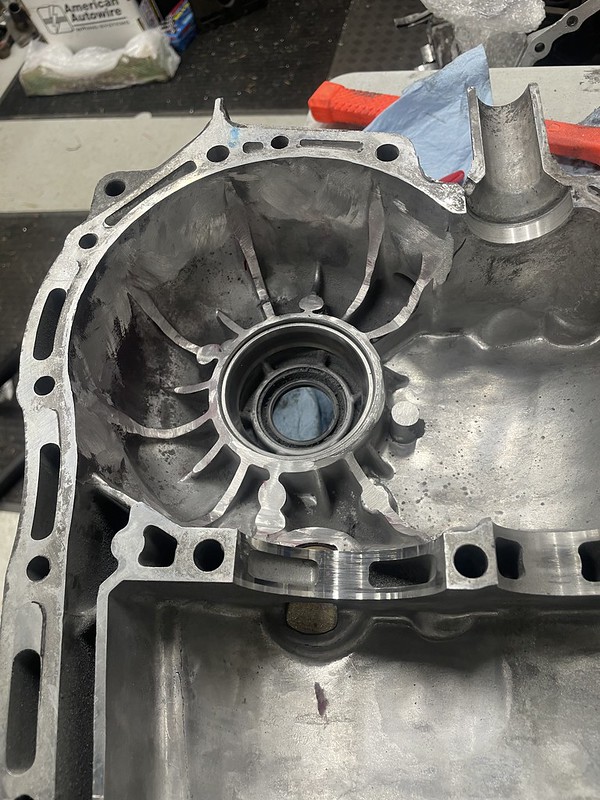

The pinion shaft is then shimmed to set the pinion depth. The Subarugears kit includes the tool needed to do this, but you have to buy the shims from Subaru. With two transmission torn down, I had enough shims to get close...but not perfect. I messaged Todd with a photo, asking if 0.05mm was close enough to zero, or did I need to get it zero'd out. He replied to ignore the tool, and simply check it with the "stock shims you took out". Uh, okay? Why include the tool then? Anyways...we'll come back to that, because it's hilariously annoying.

The next step is to mark the ring gear with grease, and assemble the transmission, torquing the case bolts to spec. You then adjust for backlash, set the bearing preload, rotate the transmission a bunch of times, and tear it all apart. Take a look at where you are at with the grease markings, reassemble and repeat. If (like me) you've never done this before, it helps to dance a tribute to the gear mesh gods, pray, sacrifice a beer on the floor (that may have just been me knocking it over), and any other spiritual things you may think will help the situation. The biggest key, however, is to focus on one measurement at a time and only change one thing in between case tear-downs, so you can learn how each adjustment changes the mesh pattern. Ultimately you need to setup pinion depth and backlash, but changing one changes the other...so don't attempt too many things at once! Three assembly/teardowns later, and if you're doing

really well you end up with some patterns like this:

I thought I was pretty much spot on, but it looks as though my gear mesh is a little loose (pattern too high on the tooth). Thing is, I'm measuring 0.005" backlash, and spec is 0.005-0.007. So if it's not the backlash, that tells me that perhaps I want to be just a touch tighter on the pinion depth. Checked with a bunch of buddies who know these things better than I do, and they all agreed I could run it as is, but maybe try and move the pinion a hair just to see.

So at this point, since I figured I was almost spot-on, I'd ask Todd what he thought. "Looks excellent, but you should move the pinion a touch. We find that 0.45mm of shims is usually the right spec." I'm sorry, what? Why didn't you tell me that five hours ago when I asked about the shims!?! ARGG! I could have had it spot on tonight if he had. I mean, not really

that big of a deal. I learned a lot, and I'm very fortunate that the guy who sells the parts replies so readily. Just hilarious considering the time frame. But at that stage, it was 11pm, and I figured I'd be smarter to go to bed and deal with it tomorrow...

-Dave