|

|

#586

|

||||

|

||||

|

On the way down to the Volksfest show, I noticed the tach needle would occasionally jump, like an electrical issue or spike. The Rally Bug has always run pertronix inside a 009 that has a roughly two-year habit of causing this sort of issue. Where pertronix usually dies instantly, in the rally bug it gets 'noisy' for two weeks and then dies. I carry points in the glovebox, but figured I could limp it home or swap them when it died completely. Now, keep in mind that I had a 40min wait at a ferry and then a 55min wait for a highway closure. I had plenty of sitting time to swap out to the points.

Of course, by this point the famous double exhaust gasket temp-fix had also blown out completely...so orange flames shooting out the tailpipe become a standard 'feature' :P The exhaust leak causes the fuel injection system to go full rich, so the combination of randomized spark, and fuel injection computer completely confused, made for a bit of a rough final leg home. Got home, popped the distributor cap, and...would you believe it? Damned thing is running points. They had simply closed up, a quick adjustment and the ignition is stable again. Whoops! As for that exhaust leak, the double gasket obviously isn't working...so I needed a new solution. Step one...draw up the part.  Second step, pull out the CNC Plasma cutter...  Clean it up a little...and this should be good to go.   Basically, instead of running a double gasket I'm simply just going to run the steel flange as the gasket...and the little bit of leakage that will occur I'll compensate for. This exhaust system only has to make it to the end of the driving season before my 'next plan' kicks in...so the band-aid fix is just fine. Besides, how else am I going to keep those sweet blue-flame backfires on decel? :P

__________________

'71 Type 1 - Rally Project '58 Type 1 - I bought an early!?! '73 Type 1 - Proper Germanlook project '68 Type 1 - Interm German 'look' project '75 Type 1 - Family Heirloom '93 Chevy 3500 pickup - Cummins Swap |

|

#587

|

||||

|

||||

|

Finally got the rear ride-height to be where I want it:

Which creates a whole 'nother world of problems. When I did the coil-over conversion, the suspension was setup to work best at stock ride height and more, for rally. Setting it up this low means there is a disproportional amount of suspension droop available, and not enough travel for bumps. The spring rate, which was technically always a problem before, is also now a much bigger problem. I need something in the 325-400lb per inch rate at the beginning of the stroke, but 600-700 at the end of the stroke. Normally one would just buy a progressive spring, but they don't make them in the short spring height I have available to me. So I started thinking about stacking two springs, and what springs I would want.  Now, given that the red spring is 8" long, and they make 4" springs, it seems like a simple conclusion. Put a 350lb and a 700lb spring in the 8" space, and call it a day? I bounced the question off of a couple of racing buddies of mine, and then spent the last two evenings going to spring-physics classes with links they send me on the internet. Spring physics get absolutely brain bending. If you stack two springs in series, you don't get a curve that starts at the lower spring rate and finishes at the higher rate. Instead, you actually get a single linear spring rate that is wildly different than you anticipated. Stack a 4" 350lb spring ontop of a 4" 700lb spring, and together the two will act as though they are a linear 233.3 lb spring. The top springs is multiplied by the bottom spring, and that is divided by the top spring plus the bottom spring, to arrive at your linear number: (TSxBS) / (TS+BS) = Spring Rate. In our case (350x700)/(350+700)=SR -> 245000/1050=SR -> SR=233.33 HOWEVER if one of the two springs reaches coil-bind, then you'll have the non-coil-binding spring acting at is 'normal' rate. So if we could make a 2" tall 350 spring, and a 6" tall 700 spring, at some measure of stroke the 350 spring would coil bind (ie: compress fully) and you'd go from a 233.3 linear spring rate to a 700lb spring rate. Hmmm... In offroad racing, this is done by something called a crossover ring. This ring threads onto the shock body inside the springs. The spacer that is between the two springs cannot slide past the crossover ring. So as the springs compress, eventually the spacer will hit the crossover ring essentially stopping the top spring from moving any further -> now you have a bottom spring acting on it's own, thus it's now acting at it's labeled rate. So, put the 350 spring on top, with a crossover ring inside, and the 700lb spring on the bottom. The suspension will have a 233.3lb spring-rate until it compresses enough to have the spacer between the two springs touch the cross over ring. At this point it will transition to a 700lb spring rate. Moving the crossover ring up and down changes where the spring-rate change happens. We're getting somewhere now. Now, I happen to know a 233.3lb spring rate is going to be much too soft to start with, as the car sinks to the bump stops on 300lb springs. So we need something in the 375-400 range to start. How the heck do I find a combination of springs that will do that? Wouldn't you know it...there are handy spring charts where someone has already done the excel math for you. Simply scour the chart to find a combined rates in the 375 range and... aww crap. A 600lb and 1000lb spring combo will do it! I suppose I could put the 1000lb spring on-top (presuming I can get one in 4" length) and lock it out with the collar to end up with a 600lb rate? But I honestly don't know. This is the point where you call your friend Ray, of Trial Engineering. Before moving to Canada Ray worked as a suspension engineer for a very prominent World Rally Championship team. Everyone has a Ray, right?  Fortunately for me, Ray enjoys a good noodling session. He also explained to me the problem with using crossover rings, or planning on one spring coil-binding. The transition between combined rate and single rate isn't so much a 'transition' but more of a stair-step. So, in our original example you go from 233.3lb to 700lb rate almost instantaneously. Not a significant issue on a long-travel off road impact (think jumps in Baja) but potentially significant on a road car. You don't want to be setup and halfway through a tight mountain corner, suspension loaded almost to the crossover and then hit a compression. It could cause some handling issues. Ray needed more info, so the suspension came apart for measurements once again:  The spring length as measured with the car at rest, along with wheel-to-fender distance. The suspension was reassembled without spring, and I cycled through full droop full compression taking measurements of the wheel-to-fender gap. All these numbers were sent to Ray, who started on some calculations. First off, he figured out the ideal starting spring rate for maximum comfort and compliance, while still holding the car off the ground at the desired ride height. He then used my ideal maximum rate (based on questions he asked about the cars handling in rally) to figure out what the ideal finishing rate would be. Then he came back with some suggestions on modifying the car. I have way too much droop, and not enough travel. Raising the car 30mm would be ideal, which is hilarious because I just spent two weeks getting it DOWN 30mm! The bump stops are trimmed as much as they can be, and the shock is dangerously close to nearing bottom-out. So, my only other option is to move the lower shock mount. This will reduce the droop, but allow us to trim the bump stop further for more upper travel. Commercially available springs are compared:  For now, Ray thinks he has found the best of the worst-case scenarios. One solution is to combine a progressive tender spring with a longer linear spring, planning for the tender spring to reach coil bind. The downside is how the car may handle at the transition. The second option is to simply get a custom spring wound in the desired progressive rate, not sure what that will cost me. The third option is to combine a shock extension with a custom lower spring perch to get me more room for mounting an off-the-shelf progressive spring which is (currently) too long to fit on my shock. OR I take these rear arms off, mount up a spare set of factory arms with mounts, and look at what setups you guys are using on your lowered German Look cars. My current setup uses 2.5" inner diameter springs, but I believe some of you are using shocks with 1 7/8" springs, which allows you to use the factory lower shock mount (just moving the hole lower). Definitely more research to be done here.

__________________

'71 Type 1 - Rally Project '58 Type 1 - I bought an early!?! '73 Type 1 - Proper Germanlook project '68 Type 1 - Interm German 'look' project '75 Type 1 - Family Heirloom '93 Chevy 3500 pickup - Cummins Swap |

|

#588

|

||||

|

||||

|

In lowering the car, we've discovered a unit problem due to my custom rear end. It was only ever built to be 1/2" lower than stock, to 2" higher than stock. In it's new lowered position, I have tonnes of droop travel, but run out of travel on compression. New shocks allow me to move 20mm of droop travel into compression travel, which is significantly better (and actually causes us to need to map out the ideal springs again). Yes, we're at the point where there is value in moving 20mm of suspension travel around. Who would have thunk?!

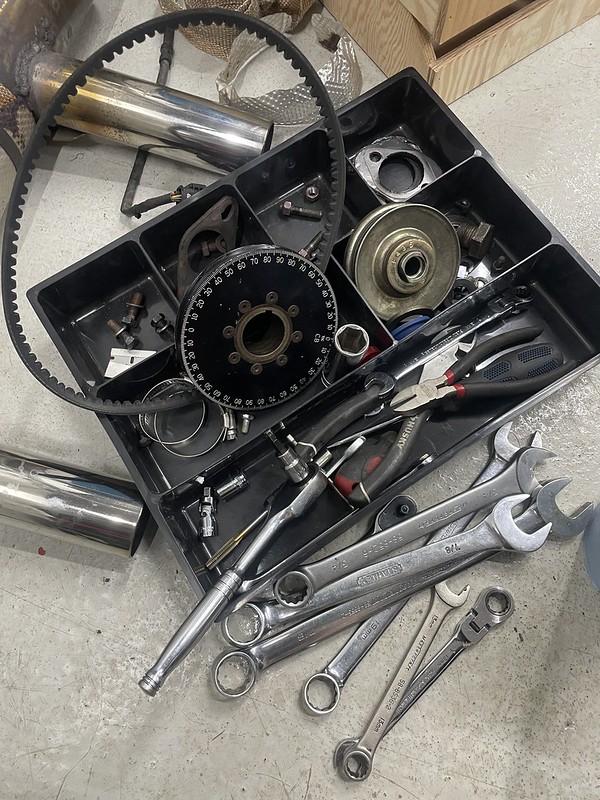

One of the items I've been meaning to address for a long while is the wear in the oil pump. Shortly after I built the car, Bugpack was purchased by Empi and dissolved. The drysump oilpump that they made, disappeared along with the Bugpack name. This is slightly more than a minor inconvenience, because the body of the pump is all aluminum...which means it does wear. None of the other drysump pumps are interchangeable without me doing new oil line configurations or more. When a stock oil pump wears against the cover, you can polish them up on some glass with sandpaper. With a dry sump pump, which is actually three pumps stacked together, it becomes a little more challenging. Mine has worn to the point that the scavenge (removing oil from the engine and back up to the tank) occasionally will stop scavenging at idle. This fills the engine with 12L of oil, and then goes to zero oil pressure. Not an issue if you're driving, it scavenges just fine above 1,100rpm. But I haven't been able to leave the car at idle unattended for a long time. Taylor and I are are going to do an event in the car this summer, and having 12L of behind you at 220F in the summer heat is less than comfortable, so swapping over to wetsump while I work on the drysump oil pump seemed like a win-win solution. As it turns out, it would be rather frustrating for a day and then a win-win-WIN solution.    A good opportunity to snap a photo and note that this motor is running an FK-8 cam. I should probably dig up all the motor specs and put there here in one post.  The Rally Bug engine bah has always been dry as a bone. So dry, in fact, that the rear sheet metal rusts out and has to be painted every so often. This is not a trait that the German Look or '58 Beetle share. At random intervals, and in a totally mind-bending makes-no-sense manner, they will spray oil all over the engine bay off the crank pulley. Sometimes it's a light bit, sometimes you are mopping up the engine bay at each driving day end wondering how it could possibly be that bad. It's so weird, I drove the German Look beetle for a day and had almost no oil, dad drove it the next day and had to mop up all the oil in the engine bay by lunchtime! It seems to make zero sense. So, imagine my frustration after swapping the Rally Bug to wetsump, and coming home from a test drive to see this:   Over the next few days I did high-rpm highway run tests, low speed city tests, mixture tests. When the oil comes out isn't consistent in time or quantity. Even weirder, the back of the pulley is almost completely dry. Whereas on the '58 and German Look it will be soaked. Comparatively speaking, it mostly drips/runs out of the Rally Bug, but sprays all around in the '58 and German Look. The drysump pulley is significantly smaller, 5" diameter, vs the stock size that the other engines run. And very quickly I figured it out...On my wet sump engines, instead of hanging an extra sump below the engine (as is typical for VW's), I'm using a 1.5L or 2.0L Accusump. It essentially holds pressurized oil ready to feed the engine if the pickup starves. So while whipping around sustained twisty corners if all the oil ends up in the cylinder head, the accusump keeps sending pressurized oil into the engine until it uses up it's 1.5-2L capacity. Typically an Accusump is set at the idle-oil pressure of an engine, or the minimum pressure you want to see. I've always set mine to 20psi. Enough to keep the bearings alive in a full-starve situation, but should have little bleed down at idle. Turns out, at 20psi I'm probably emptying the Accusump at idle, waiting at a red light. My current theory is the oil level rises high enough to become an issue inside the case, resulting in oil pushing past the crank pulley onto the tin. If the only thing I changed was drysump to wetsump, it can't be blowby or other engine issues. So let's try a sandseal to see if that will work? Rob Frose overnighted a sandseal setup from AVR, and I went to work fitting it to the car. 250km of high-revving, 20min of idling, and any other test I could throw at it...dry as a bone. Guess I need to order some sandseal setups for my other engines :P My ignition issue I was experiencing on the way to the show and back had gotten worse, so I decided to swap out my CB Blackbox setup to the Magnaspark II that I'm running in the other cars. I got 85% through the swap when I found the damage in the wiring harness I use with the blackbox (user error) and the likely problem. I was already 85&% done, so I decided I would just continue with the swap. The last step is to change out the ignition mapping with the fuel injection, which was going to be a problem. The laptop I have for the car, which runs Windows XP, has had a drive failure. By some sort of miracle, I actually backed up the files and maps I had a few weeks ago. Miracle number two? I actually got the CB software running on my Macbook using Parallels and windows 11. The only problem is the mac won't recognize the cable conveniently ziptied all through the car, and I am going to have to replace it. Swapped the ignition settings, and all my problems are gone. The only issue is the map I was using is right-messed-up due to trying to tune around ignition problems, and forgetting that I have to recalibrate the throttle position sensor at every map change. Who knows what that poor computer has been trying to compensate for. So I loaded in the last known good map from a couple of years ago, and will have to work back towards a more efficient tune. I did some mileage tests on the now current-map, and then decided I would note it somewhere on the car since I seem to be forgetting more about it than I remember. Gave myself a 5 litre window too.    Lastly, I've been thinking about that upcoming trip with Taylor...and where we're going to put camping and weekend gear. Even just a little extra storage space would be nice. The battery area always seemed like such a waste of space, and I had a spare aluminum cooking sheet...so here we go. Extra luggage capacity! I think once I decide to learn composite constructions, re-doing this in Carbon might be one of my first projects.

__________________

'71 Type 1 - Rally Project '58 Type 1 - I bought an early!?! '73 Type 1 - Proper Germanlook project '68 Type 1 - Interm German 'look' project '75 Type 1 - Family Heirloom '93 Chevy 3500 pickup - Cummins Swap |

|

#589

|

||||

|

||||

Gawd this car looks awesome. :P Having finally pulled it out of mothballs, Taylor (my girlfriend) and I took it on the Classic Car Adventures Rush to Gold Bridge. This event is a mixed tarmac and gravel event, which goes to a different destination or challenge each year. This year we went to Bella Coola, a very remote mountain town in British Columbia. To get there, you have to take Hwy 20...a significant stretch of which is still gravel, despite it being the only road in and out. Until 1953 the highway ended 137 km (85 mi) from Bella Coola. The Government considered it impossible to make a road to Bella Coola. Residents fired up a Bulldozer (brought in by barge) and built the rest of the road themselves. 70 years later, and the road is still single lane in sections and descends 43 kilometers with switchbacks and zero guardrails or other safety items. Perfect for a classic car event!     The event was going incredibly well, all the way down to Bella Coola, and up the hill the next morning. We filled up with fuel at the top of the hill, strapped lunch to our manifolds (seriously) and made our way an hour down the road to a park where we should find lunch hot and steaming in the engine bay. For the cars that strapped lunch to the exhaust manifold, it was perfect. For cars that mistakingly strapped it to the intake manifold? Well refrigerated! Fortunately we had a BBQ waiting at the lunch spot to heat up everyone’s lunch :P About 200km from the fuel stop, however, and the Rally Bug ran into a slight issue.  While a couple of cars went down the road to find some fuel, I started to think about how I could have possibly ran out of fuel about 200km from our last gas station stop. I remember putting the nozzle in the car, and being stressed about making sure everyone stopped to put their lunch on the manifold properly. I remember taking the nozzle out of the car, and the fact that the gas pump didn’t give me a receipt. But what I couldn’t remember is whether I was sure I actually filled the tank. Did the pump click off right away, and I just assumed it was full? Hmph. After a road-side rescue, we filled up at the next gas station and went for the last gravel leg, a roughly 300km trip on gravel. We were running behind for dinner, but while driving I came up with a second theory besides just “I don’t know how gas stations work”. The Rally Bug has two wide-band 02 sensors. One works with the fuel-injection computer, the other a gauge on the dash I can read. When we lost the gauge on the way up the hill, I thought nothing of it. Given how long the car has been in mothballs, could be a wiring fault or a sensor failure. After a while, I realized that rocks could have taken out the sensor…wait, what if it took out the sensor for the fuel injection computer too? But the car was running sooooo well…   …until it wasn’t.  Taylor and I got to camp in the middle of nowhere on a forest road. Coffee made by the camp stove, ‘charcuterie’ of snacks, 4 hours of no cellphone or radio while we hoped our friends could find us with fuel. It doesn’t sound that bad, but when we looked at the map before they left, we all agreed it should be “about an hour” before they’d get back with fuel. We did make it out of the woods, and the next morning I confirmed that both 02 sensors had major dents from rock hits. I know back when I was running the car regularly it had shields on the 02 sensors…so where did they go?! Hmph, a mystery for another day. Limped it home, burning 2x the fuel it should (and probably washing the cylinders down).   Into the shop for some post-event maintenance!  -Dave

__________________

'71 Type 1 - Rally Project '58 Type 1 - I bought an early!?! '73 Type 1 - Proper Germanlook project '68 Type 1 - Interm German 'look' project '75 Type 1 - Family Heirloom '93 Chevy 3500 pickup - Cummins Swap |

|

#590

|

||||

|

||||

|

Tnx for the great write-up!

The gold wheels look awesome btw. |

|

#591

|

||||

|

||||

|

The list of items to tackle is vast, but when you read through it not exactly difficult. Swapping out a new fuel cap, for instance, super easy.

Untitled by Dave Hord, on Flickr Untitled by Dave Hord, on FlickrMade up some replacement metal 02 sensor shields. These are only needed for use on gravel roads, I've never damaged a sensor otherwise, but clearly needed on gravel roads! Material is something I got from DCI Performance in Australia, but can't seem to find it on the website anymore. Need to figure out what it is...as I've used the last of it!   These next two images, grabbed from my IG stories, pretty much says everything...   Digging into it, it would seem that I had no less than three sets of power wires run from various spots in the car to where the Rally computer mounts. I expected two, because I used to run a Brantz rally computer, but swapped it out when it stopped functioning correctly. The Helios unit here was supposed to be a temporary mount, which may explain wiring setup number two. But then, there was a permanent set of power wires (complete with wire loom) that really confuses me. Why didn't I pull the temp set out? There were two sets of sensor wires too. One was running to a speedometer cable-run sensor, that was only half hooked up, and the other to the GPS speed sensor. My Brantz is definitely the preferred rally computer, but as it has to go back for repairs I cleaned out all the wiring and set this car up to simply use the Helios unit on the GPS sensor. From a rally perspective, this isn't ideal, as the GPS sensor occasionally takes some time to find a satellite after start up and you lose distance when driving through a tunnel. Since I don't really use the car for TSD or performance rallies anymore, just the Classic Car Adventures tours, it's "close enough". Cleaned up, and moving to deutsch-style connectors.   The tail lamps on the car have had issues over the years. The right tail lamp is famous for losing the running lamp, which was simply a matter of epoxying the bulb holder into the metal reflector. But on our last event I would (apparently) lose the left tail lamp at times, and then the right. But never the two at the same time. I've been sitting on a set of LED tail lamps for a few years, having not swapped them over because I prefer the authentic european lamps with the orange turn signal. Alas, the wheels are no longer Salzburg appropriate...so time we lose the tail lamps too. Popped the new ones on...  ...and promptly had a non-working left running lamp. Keep in mind, it was working moments earlier when I used it to confirm wiring colours for each circuit! Lamp off, electrical meter out, no power to the housing. GRRR. Spun all the ceramic fuses, and it worked. Moments later, it went out. Hmmm. Further inspection determined I have a fault in the fuse box, which is a bit of a fun problem. It's about this time that I started thinking heavily about just tearing the whole car down and rewiring it from scratch. I did my MG Midget last winter, made a whole new harness with deutsch connectors and a modern fusebox, and it's fantastic. No more British electrical issues. This car has had so many patches and additions over the ten years, and I'm not as big a fan of the anderson powerpole connectors as I was when I built it. Also, I know why I went with factory style fuses for the two fuse boxes...but like the wheels, it's time to modernize. I need to pull the windshield wiper assembly if I'm going to fix the pivots, but there is a whole whack of rally-related wiring and connectors in the way. I'm sure when I built the car I thought it was nice and modular and easy to pull out sections...but looking at it now, with 10yrs of wiring diagrams lost to my head. I'm not so sure! The Rally Bug needs to have a 'quick turn around' in the shop this round, as it's the car most ready-to-go for events in 2024. I need to get the '58 in and ready for California Mille, and then I'd like to prep the German Look. After that's done, I can relax a little and consider whether a two week re-wiring job is worth it. So instead, for now, it's going to be clean up where I can...ignore what I have to...and move non-critical items off the list if necessary. I managed to 'fix' the fusebox for the moment, but I'll get a 10A blade fuse ready just in case I have to bypass it :P It was about this point that it dawned on me. What if, the Brantz rally computer isn't damaged internally...and it was just the flaky wiring on the car? Unboxed it from the repair-return shipment I had prepared, and hooked it up on the bench. Sure enough, darned thing is working perfectly. AND I've just finished modifying the car to use the less desirable Helios! ARRRGGG! Well, I have been considering outfitting all the cars with rally odometers this winter (Taylor really appreciated being able to follow the mileage with the route book)...so I guess I have a Brantz to pop into the German Looker now. Sigh. Side note...why is it the Rally Bug that is the car that doesn't leak any oil!?!  -Dave

__________________

'71 Type 1 - Rally Project '58 Type 1 - I bought an early!?! '73 Type 1 - Proper Germanlook project '68 Type 1 - Interm German 'look' project '75 Type 1 - Family Heirloom '93 Chevy 3500 pickup - Cummins Swap |

|

#592

|

||||

|

||||

|

Thanks! When I first drove the car out and looked at them, I actually hated it. It's taken a few weeks, but they've fully grown on me. Love it now.

__________________

'71 Type 1 - Rally Project '58 Type 1 - I bought an early!?! '73 Type 1 - Proper Germanlook project '68 Type 1 - Interm German 'look' project '75 Type 1 - Family Heirloom '93 Chevy 3500 pickup - Cummins Swap |

|

#593

|

||||

|

||||

This is how normal people wash their cars...right? More on the Rally Bug next week...

__________________

'71 Type 1 - Rally Project '58 Type 1 - I bought an early!?! '73 Type 1 - Proper Germanlook project '68 Type 1 - Interm German 'look' project '75 Type 1 - Family Heirloom '93 Chevy 3500 pickup - Cummins Swap |

|

#594

|

|||

|

|||

|

Dave, I love your rally car! Pretty for of the GL too.

H2OSB

__________________

johnL (aka H2OSB) '74 1303, Outlaw sedan (with a GL flavor) |

|

#595

|

||||

|

||||

|

Sooo...that update.

I was out testing the Rally Computer install and the other updates to make sure the car was good for events next year. Took it to a buddies barn, hung out for a while, and then headed home via a nice twisting road near the lake. Coming up over a crest, on a slight right curve, a truck was going the other way. I'm not sure if this came out of the dually tires, or he hit it on the road, but this rock came spinning and flying across the road. I was cutting to the opposite lane when it suddenly dawned on me he could be towing a trailer with no lights. The moment of hesitation meant I wasn't going to clear the rock.  Let me tell you, the sound was unreal. The engine shut off, and I was sure I was going to find a long trail of oil once I stopped. Checked the road, no oil. Under the car, no oil. The suspension mount, however, took the brunt of it. The passenger side control arm mount is heavily damaged and cracked, the frame head is heavily dented and damaged. It's now an insurance claim...whole frame head has to be replaced. Fortunately Hagerty has been excellent so far. Adjuster called me back within 48hrs of the claim, and damage assessor came by my shop today to assess it. Should know before the end of the week what the decisions are.

__________________

'71 Type 1 - Rally Project '58 Type 1 - I bought an early!?! '73 Type 1 - Proper Germanlook project '68 Type 1 - Interm German 'look' project '75 Type 1 - Family Heirloom '93 Chevy 3500 pickup - Cummins Swap |

|

#596

|

|||

|

|||

|

yikes, that was probably scary as hell!

I hope the insurance would cover up this kind of damage, it takes a lot of work. And maybe some wanted upgrades too in the same time?

__________________

VW Super Beetle 1303 1973 Kolibri Grün Metallic |

|

#597

|

||||

|

||||

|

Insurance is going to cover it. That part I don't have to worry about.

I'm hemming and hawing on the idea of upgrades, since I'm going to have to strip the body and pull it from the pan. There are lots of changes I could make to the car to make it more 'streetable'...but then, is that really the Rally Bug? Honestly? At this stage it's likely to just get the unused items removed, holes filled, and maybe a whole new wiring harness. But then the damage assessor was looking at the front end of the Blue beetle and asked, "why wouldn't you put that front end [the iMohr] in it, since you've got to cut it all out anyways? Hmmm....

__________________

'71 Type 1 - Rally Project '58 Type 1 - I bought an early!?! '73 Type 1 - Proper Germanlook project '68 Type 1 - Interm German 'look' project '75 Type 1 - Family Heirloom '93 Chevy 3500 pickup - Cummins Swap Last edited by owdlvr; November 9th 2023 at 15:28. |

|

#598

|

|||

|

|||

|

Options, choices, wannahaves and musthaves.....always a struggle. But a Rally Bug is a Rally Bug, not a Street Bug.

So the phrase "Because racecar" might help making choices?

__________________

VW Super Beetle 1303 1973 Kolibri Grün Metallic |

|

#599

|

||||

|

||||

|

This is excellent advice. I think I also need to keep it a little true to the original ethos of "replica" with modern materials. It seems a little sacrilegious to eliminate the front struts the factory was so successful on.

__________________

'71 Type 1 - Rally Project '58 Type 1 - I bought an early!?! '73 Type 1 - Proper Germanlook project '68 Type 1 - Interm German 'look' project '75 Type 1 - Family Heirloom '93 Chevy 3500 pickup - Cummins Swap |

|

#600

|

||||

|

||||

|

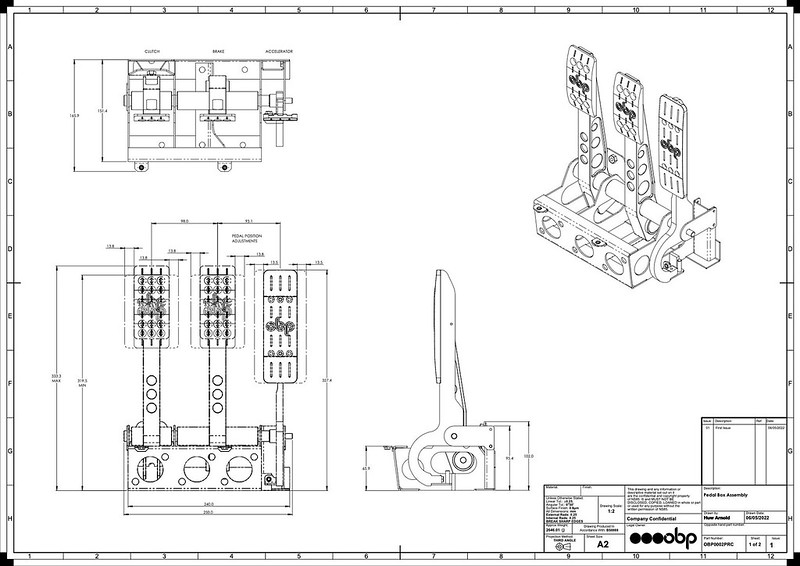

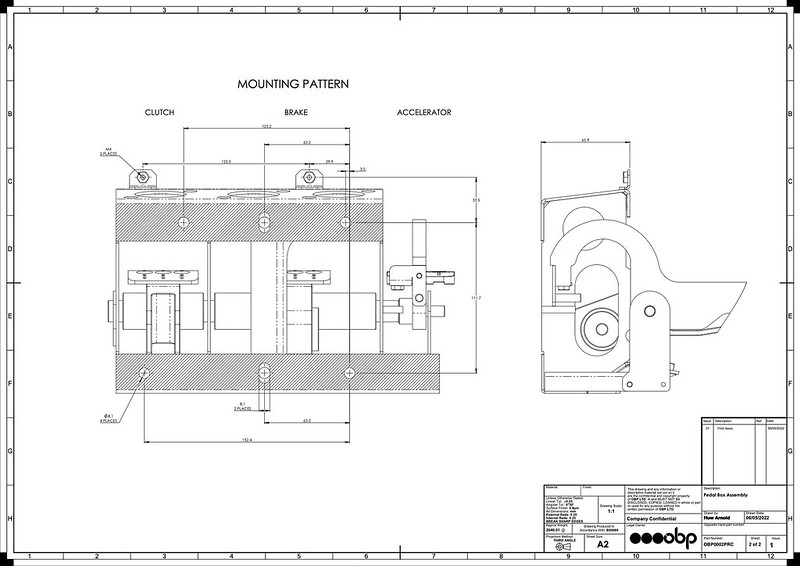

I don't have a settlement yet, but I did get permission to start tearing it down for the repairs...

Since the body has to come off the pan, I've decided to pull some funds from the Family Heirloom project and repaint the Rally Bug. After three years of winter rallies, and a further 7 years of running, it has a couple of spots that could use it. The paint was acceptable at the time, due to budget, but could be much better. So the plan is for a non-colour change "tape and spray". Being the guy I am, though, I'm going to remove absolutely everything necessary to get a good outside repaint. The front hood on the car was an accident-repaired hood. Turns out I have a factory original front hood that is perfect (just yellow) thanks to a friend Darren, so the original Rally Bug hood will become artwork in the shop. Interestingly, it turns out I have _two_ spare hoods, three if my other spare still exits at my buddy Rob's house. So I think that gives me a chance to spray full silver body, and a set of black hoods as well. I very carefully asked my buddy Bob, who's a 'stock is right' kind of guy, what he thought about the turn signals on the front fender. To my surprise he replied we have to fill them and go mexi-bumper...which confirms my gut reaction about the choice. As soon as the gold wheels went on the car, it gave me permission in my head to stray from the "Salzburg Replica". Just gotta be sure I can go back that way if I choose.  Looking a little deeper at the wiring, I've got some challenges ahead. The original harness I built for the car is quite robust...but definitely not built to be modified. I damaged the front rally light harness trying to get it out of the car, apparently I build part of it after putting it through a body grommet. The way I did the Techflex wiring cover I can't actually splice into the harness for modification or repairs without damaging it, and possibly daming the internals. So, my idea of potentially modifying sections of it are pretty much out the window. If I simply leave the wiring harness and tear out anything I've added over the years, I think it will be fine. There's nothing that isn't working correctly on the original harness, although there are some circuits no longer being used. It does also have those original-style fuses which isn't great. I'll need to build a secondary harness for post-build editions, which is probably the fastest/cleanest way to do things. But it does have some negatives. I want to change the switches on the dash, and I need to dig out the gas heater wiring harness, which was (apparently) laid into the car first...under the main harness. I fear disturbing anything in the rats nest is a recipe for disaster.  Rewiring the entire car, though, is going to be a huge undertaking. I know what I want to do. But do I have the time (and money) to do it?   Looking ahead, I'm considering at the seat mounts I built 15 years ago (for the white '69)...and they simply have to go. If this was a fully-caged car, it would be easy. A couple of bars from the sill to the tunnel, and the job is done. It's only got a rear hoop, and I want to keep the ability to separate body from pan (especially now) so I need to come up with another solution. I talked it over last night with some race car fabricating buddies of mine, and I think we've got an idea sorted out. I'm also thinking it's a good time to upgrade/change out the pedal box. The one I'm using isn't ideal, I've had to hack out the napolean hat on the tunnel, and on the front firewall to make it fit. I will have some sheet metal repairs to do on the body, but I'm thinking a different setup might be in order. I messaged Kevin Hale about the one he's using in the Ghia racecar he's building (Ghia Raketenhase on Facebook) and he replied in less than 10min with a video and tape measure showing me all the measurements. His OBP unit won't fit in my car (14.25" throttle pedal height) but they make one that is merely 12" to the top of the pedal. Will be measuring once I'm done typing this to see if it's an early Christmas present for me!  https://www.obpltd.com/product-page/...-pedal-system/ https://www.obpltd.com/product-page/...-pedal-system/ OBP-1 by Dave Hord, on Flickr OBP-1 by Dave Hord, on Flickr OBP-2 by Dave Hord, on Flickr OBP-2 by Dave Hord, on Flickr

__________________

'71 Type 1 - Rally Project '58 Type 1 - I bought an early!?! '73 Type 1 - Proper Germanlook project '68 Type 1 - Interm German 'look' project '75 Type 1 - Family Heirloom '93 Chevy 3500 pickup - Cummins Swap |

|

| Currently Active Users Viewing This Thread: 2 (0 members and 2 guests) | |

|

|