|

|

#1

|

|||

|

|||

|

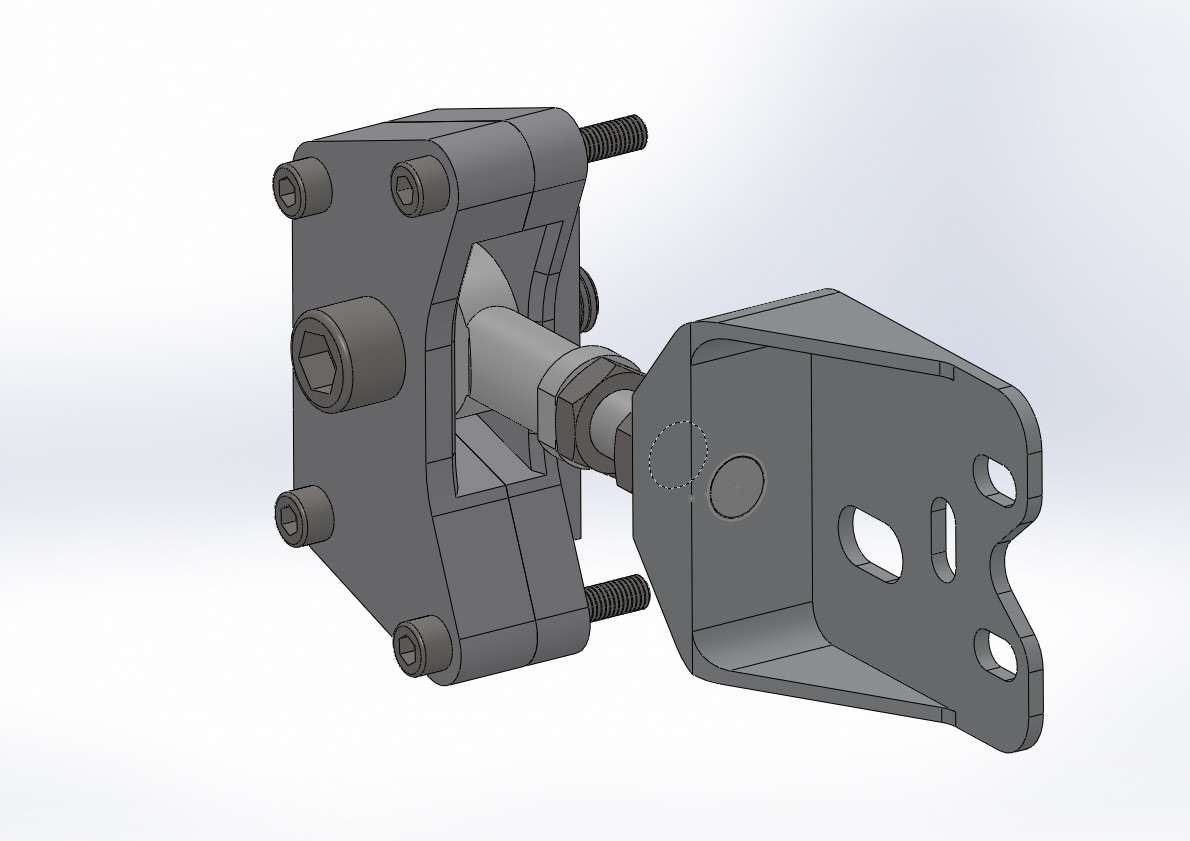

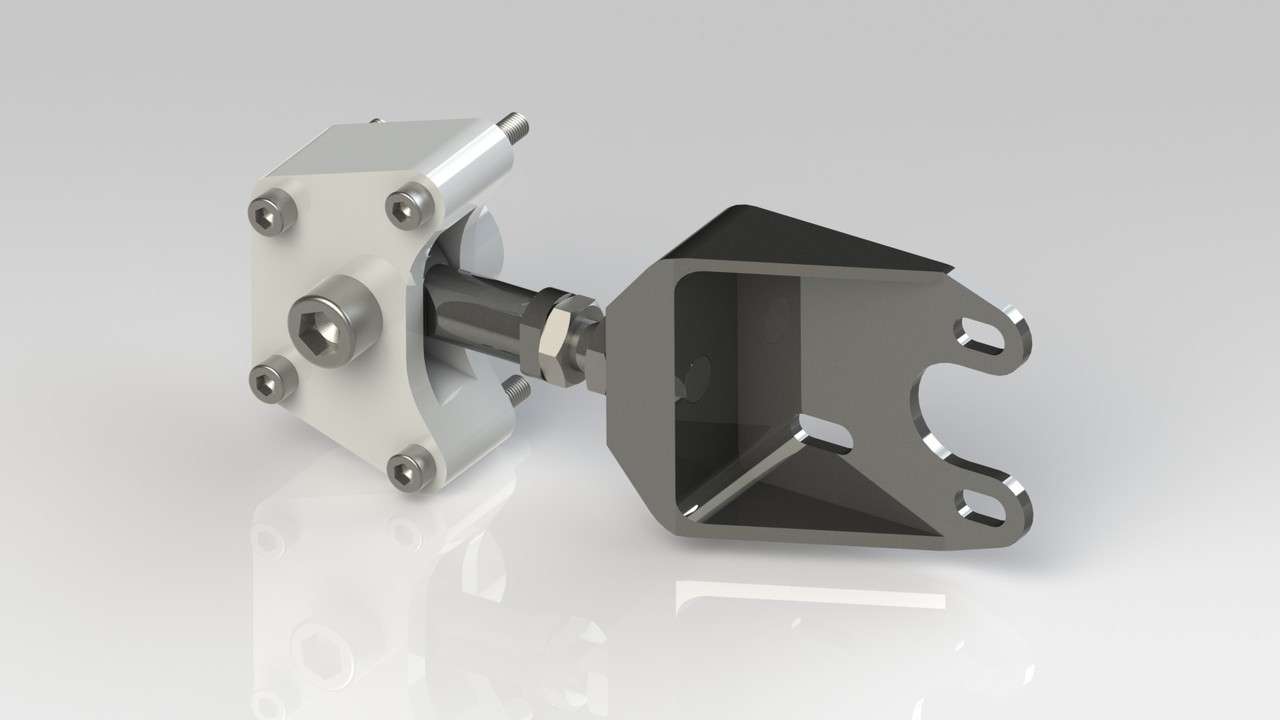

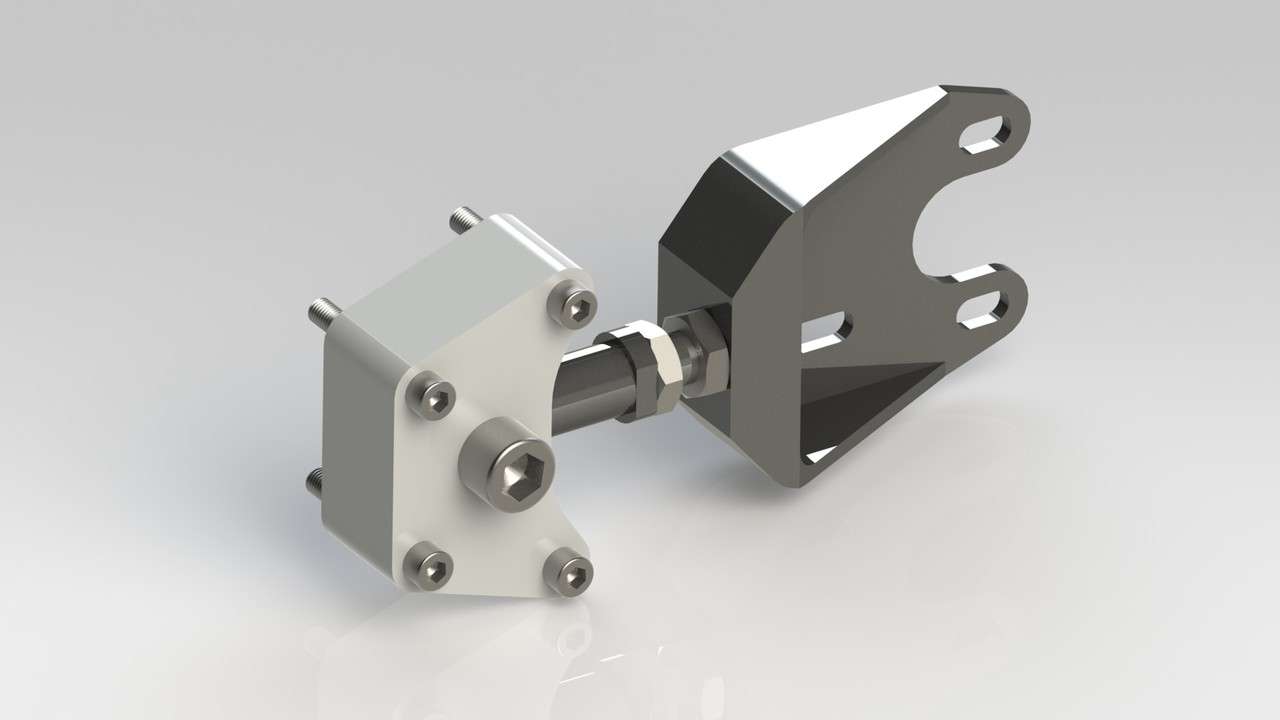

CNC made aluminum Uniball rear suspension system

I am making similar uniball system for rear suspension, what remmele, MBT, red9 and others are offering for 944 aluarms.

All parts will be made from 7075 T6 aluminum, threaded bar is made from 4130 chromoly. Inner part of the uniball housing supports itself to the end of the torsionbar housing. Includes all bolts and Hirschmann M20 uniball joint. Uniball joint is supported from both sides. Nothing is welded on this kit. I will make as many sets as people want, but from order only. Price will be 800 euros, due to higher machining costs, machining takes about 1 hour per part. To every kit i can have made little custom features, since i will be making these one kit at time. I can also put false value for customs  50% payment required in advance, so i can order materials and uniball joints etc. Moneytransfer and paypal works for me. PM or email me if you want one! alexstorskrubb@jippii.fi Here is second updated model and one real one with remmele uniball kit, first cad picture is for 944 aluarms, and second is for 924/beetle steel arms.

Last edited by -Alex-; March 9th 2013 at 08:47. |

|

#2

|

||||

|

||||

|

Some one in the US making these?

Is anyone in the US / Canada making these? I need a set that's supportive of 944T trailing arms...

PM me and let me know. thanks! |

|

#3

|

|||

|

|||

|

Alex,

Have you already made a set of those? I thought that I had seen those before but could not find the post. I guess you cant use the uni-ball system and still retain the torsion bar. I would like to keep mine and just have some helper coilovers like they use on the 944. Randy

__________________

Unix is a "user friendly" operating system. Its just a little particular who it is friendly to. |

|

#4

|

|||

|

|||

|

Sorry, i havent made these yet. Having hard time to find strong M20 uniball here in finland, Fluro or Hirschmann i would prefer. Each cost about 60-75 euros each, yikes!

Also found that SKF makes these too, should be strong enough, static 51KN and dynamic 31KN. Our use is 80-90% static. http://www.skf.com/skf/productcatalo...odid=208400017 |

|

#5

|

|||

|

|||

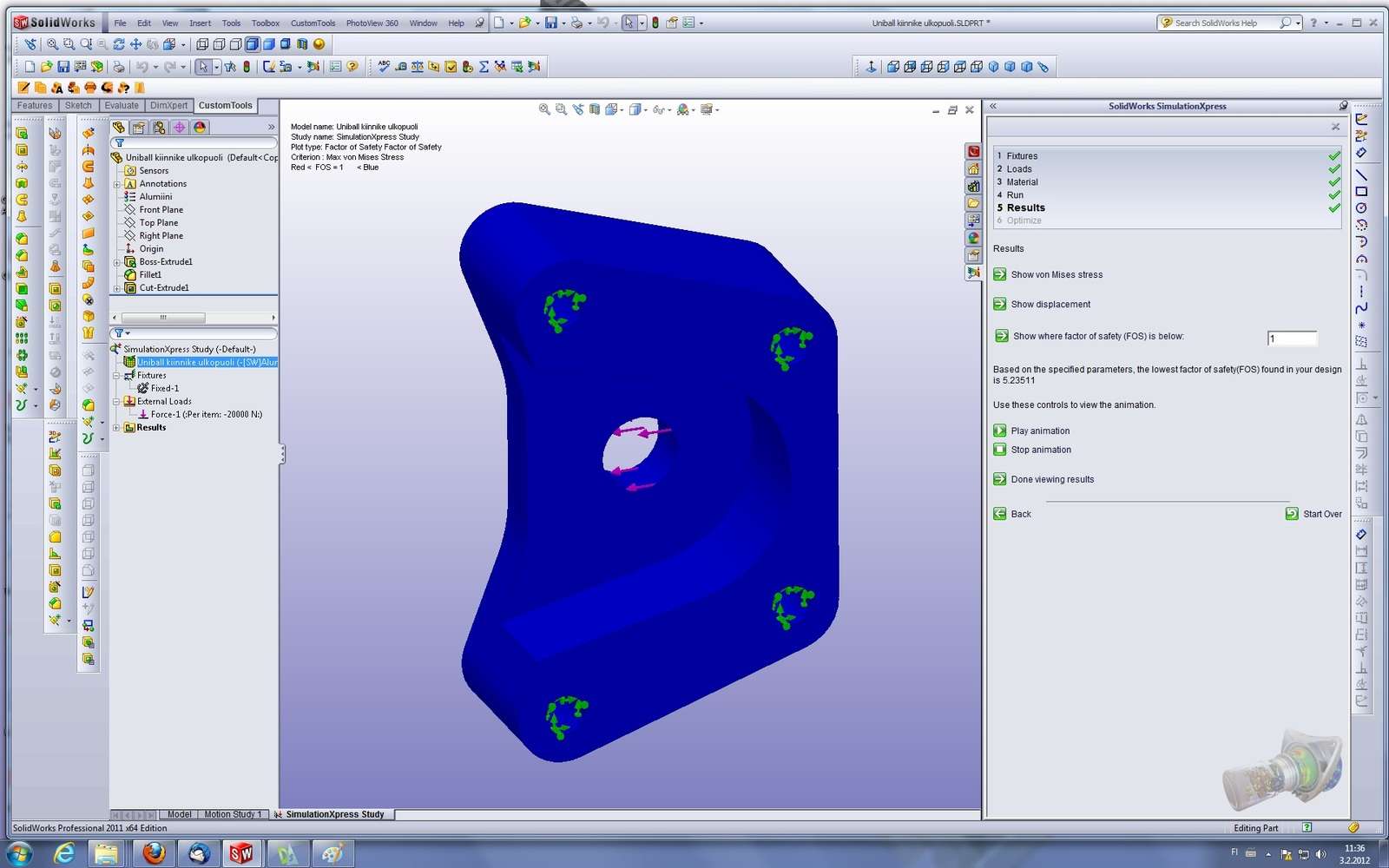

More info about my design and its strength. Small bolt holes are 10,5mm and bolt holding uniball is 20, so there is very little "slop". Actually there is M20 thread on the inner part. I did few strenght tests with solidworks simulation tool, using 6082 T6 material. I have chosen Hirschmann M20 joint, which can stand 4500kg static load and 9000kg dynamic load. Small bolt holes were used to "fix" the part and "force" from uniball bolt hole. Force is 2000kg per on 20mm hole, force direction to the back. Inner part factor of safety is 3,5 and outer part factor of safety is over 5. Putting these two parts together should make a strong housing for uniball joint.

Last edited by -Alex-; February 3rd 2012 at 16:14. |

|

#6

|

|||

|

|||

|

Hey Alex,nice model... I'm using SolidWorks as well (10 years know).

I would like to see the stress and strain charts, max values etc and deformation as well... What factor of safety are you using? Do you need some calculations for input forces suspension dynamics, braking etc?? if so pm me Chris

__________________

Aircooled 4ever 1973 1303 going towards GL |

|

#7

|

|||

|

|||

|

Hello, i have been using solidworks about 6 years. I found few litlle weak spots from the bracket, so i redesigned it.

I am not using any preferred factor of safety, but bigger i get, better it will be. All tests have been done with 20000N=2000kg force. I tried also different directions the with same force on these uniball housings per part, i am getting 2 or higher factor of safety  I could try get the stress, strain and deformation charts. Bracket will be made still from S355 steel, but i would prefer Optim 500 highstrength steel, which also you can get up to 60mm thicknesses, the best material would be 7075 aluminum, but it would rise the price of this kit. |

|

#8

|

||||

|

||||

|

Very, very nice!

What part is the 'bracket'? Anything connected to the trailing arm should be as light as possible as its unsprung weigth. Alu would be preferable over steel with that thinking. |

|

#9

|

|||

|

|||

|

Bracket is the part that used to attach whole system to the arm

Uniball bearing housing is aluminum. Uniball bearing housing is aluminum. Yes, i would too prefer aluminum, definetly the 7075 T6 series aluminum, but steel bracket is in this pricerange. Strengths: Normal steel is 355N / mm2, 6082 T6 aluminum is 270N / mm2, 7075 T6 aluminum is about 500N / mm2 |

|

#10

|

|||

|

|||

|

All test done again with 2000kg.

Uniball housing outer part stress chart http://img845.imageshack.us/img845/9...keulkopuol.jpg Uniball housing outer part displacement chart http://img814.imageshack.us/img814/9...keulkopuol.jpg Uniball housing outer part when load is 10 000kg, factor of safety is 0.85, notice the red little weak spots  http://img707.imageshack.us/img707/9...keulkopuol.jpg Arm attachment part, FOS is 1.38 with 2000kg load. Arm attachment part stress chart http://img714.imageshack.us/img714/5...nikestress.jpg Arm attachment part displacement chart http://img845.imageshack.us/img845/3...kedisplace.jpg Arm attachment part when load is 6000kg, factor of safety is 0.45, notice again the red little weak spots  http://img221.imageshack.us/img221/3...e16000kgyg.jpg |

|

#11

|

|||

|

|||

|

These look amazing. Will they work with the early steel arms?

__________________

1969 German Looker in progress: 1776 turbo EFI motor (eventually!) Built IRS Box 944 Turbo Brembos (Fr) 964 C2 Brembos (Rr) |

|

#12

|

||||

|

||||

|

I'm very interested in getting a set of these, how soon are you going to start making these and what kind of fulfillment time do you expect before getting them shipped?

|

|

#13

|

||||

|

||||

|

How far into the torsion tube (if at all) do your mounts go?

-Dave

__________________

'71 Type 1 - Rally Project '58 Type 1 - I bought an early!?! '73 Type 1 - Proper Germanlook project '68 Type 1 - Interm German 'look' project '75 Type 1 - Family Heirloom '93 Chevy 3500 pickup - Cummins Swap |

|

#14

|

|||

|

|||

|

I will be only making these from order, and i want 50% advance to get materials and joints.

I can also make all parts from 7075 T6 aluminum, which is twice stronger than 6082 aluminum and third stronger than S355 steel. Extra expense is 110 euros if you want everything from 7075 T6. But 6082 and S355 can also handle the stresses wery well. My system at the moment doesnt intrude into torsionbar housing, but i am thinking that it could be like this, at same time it also stops water getting into TB splines.

Last edited by -Alex-; February 11th 2012 at 05:05. |

|

#15

|

||||

|

||||

|

Quote:

The intrusion into the torsionbar housing seems not needed unless you run a dailt driver with these. Less the nose it would also save some expensive alu and again, weight  Interested, but need to build up my engine first again.. |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|