|

|

#16

|

||||

|

||||

|

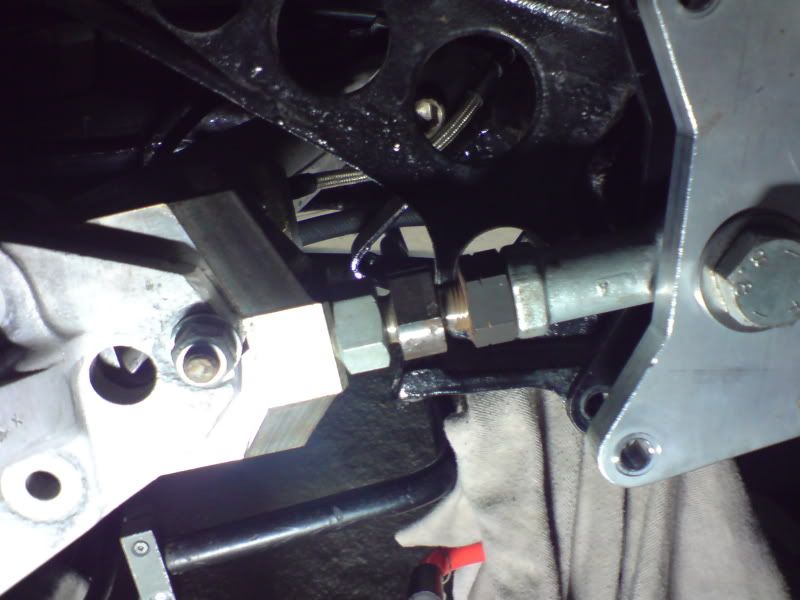

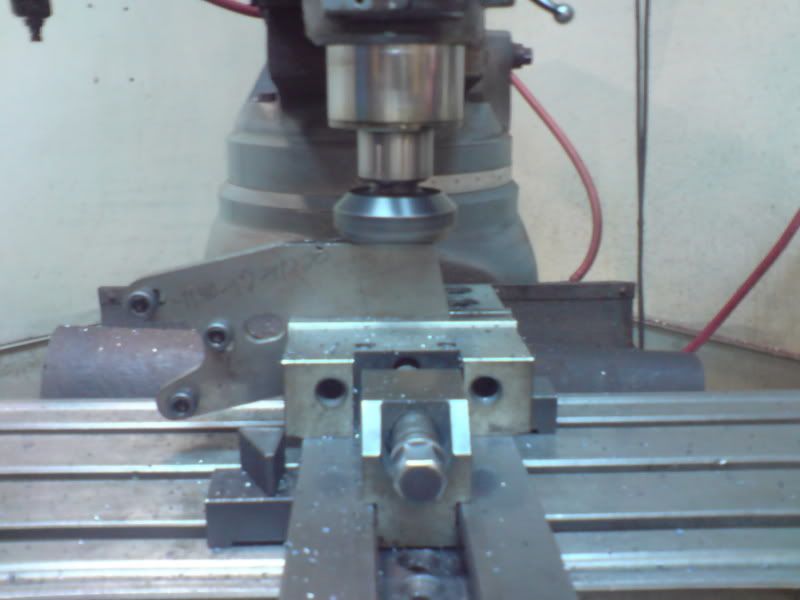

Got a set of BBS LM's out of Miami, last year. Found out they wouldn't fit without some thinking. The Remmelle hardware was hitting the inside of the wheel, so the wheel couldn't be bolted up. I was determined to make it work. Decided to try and make my own setup to allow clearance for the deep(ET65) rim/tire. I'm just finishing them up now, almost a year after starting them.

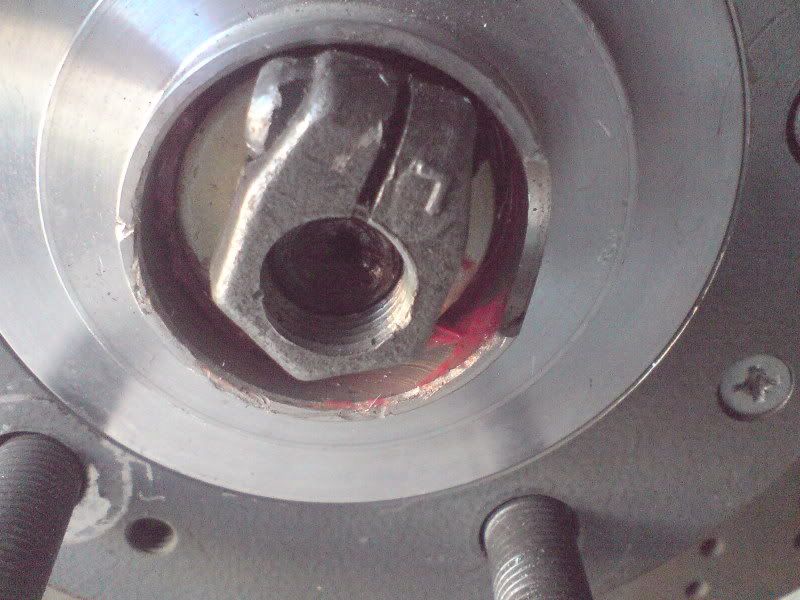

Should i narrow up that springplate some more? Need to do get them welded and coated. Thinking silver anodize/powdercoat. Local shops?  Sooooo the 18x10 LM's will now fit. It's a very tight squeeze that will need some grinding of that 1 bolt.   Will the sidewinder exhaust fit on the inside of that tire? Who knows...... We'll see......... I can't get the front wheels on. The LM's have a slightly smaller lug hole than the Dyno's. The Dyno's have always been a bitch to pull on/off. The studs look a little off. Could be bent? or not seated properly. Guess i will have to pull off the front brakes, AGAIN, and get new studs. Or drill the LM holes the same size as the Dyno's. Pic below has the wheel just barely on the studs. Couldn't push it on.   Lanner from Vdub Engineering fixed the front hubs to get the spindle nut sitting flush. This is how they were. Didn't like that at all.  Pete

__________________

'72 super '65 bus '52 split Last edited by petevw; May 7th 2009 at 02:27. |

|

#17

|

||||

|

||||

|

Quote:

The 'whacking' to drive the studs all the way to properly seat and be perfectly perpendicular is is scaringly great (ask me how I know...), so I can imagine this could be the (simple) cause. |

|

#18

|

||||

|

||||

|

Pete,

That bottom coilover bolt looks a tad long. There will be a substantial bending moment on the end of it particularly as you are exclusively using the coilover rather than torsion bars. Is there a clearance problem with the damper body on the alloy arm? Clive |

|

#19

|

||||

|

||||

|

Pete your car is looking nice!

I like what you did with the oil cooler, are you going to go dry sump?

__________________

GL ghia restoration: http://s473.photobucket.com/albums/r...20restoration/ __________________________________________ |

|

#20

|

||||

|

||||

|

The project looks awesome Pete ! I can't wait to see you driving that beast.

Sandeep |

|

#21

|

||||

|

||||

|

Nice Work Buddy...

can't wait to See it out THIS summer  Chris.

__________________

74 Std. GL 08 Vw rabbit 18 WR250R 07 Chevy 3500 Dually |

|

#22

|

||||

|

||||

|

Quote:

Quote:

When i get some weight in it, the uniball mounted and aligned, i'll have a better idea where the damper will sit. I'll then machine the spacers to get that bolt in further. When i get some weight in it, the uniball mounted and aligned, i'll have a better idea where the damper will sit. I'll then machine the spacers to get that bolt in further. Quote:

Quote:

Thanks for the comments guys! Appreciate it. Pete

__________________

'72 super '65 bus '52 split Last edited by petevw; May 7th 2009 at 13:17. |

|

#23

|

||||

|

||||

|

Looking at this pic, what are the 4 holes all about on the springplate?

The 2 round ones on the left have regular bolts to bolt to the arm. The far right hole has what looks to be a camber bolt with a huge hex head on the inside. Does the middle hole stay empty? Does it need another bolt? I can't recall if i have this "camber bolt" on the drivers side. I'll have to look again. Is the Camber bolt used for setup, and them removed after cranking down the other 3. Am i way off here? Pete

__________________

'72 super '65 bus '52 split |

|

#24

|

||||

|

||||

|

I love seeing fat steamroller tires on a bug, it's just awesome. I don't know why but one of my favorite parts on your car is the CF crotch cooler doors. How much wider are the rear fenders? Keep up the good work and keep the progress pics coming

|

|

#25

|

||||

|

||||

|

If i remember correctly, the fenders are 1.5inch wider.

The crotch coolers are just a carbon plate at the moment. I plan to make them functional flaps in the future. I have the grills and springs for them, just need to make the hinges and grill support. I like them too......

__________________

'72 super '65 bus '52 split Last edited by petevw; May 8th 2009 at 05:00. |

|

#26

|

||||

|

||||

|

Looking REALLY nice, love the wheels.

Jason

__________________

If I could just get paid for my sleepless nights.... 1960 VW Bug UBRDUB Walkaround 1st Drag Run Dyno Run Oval Ragster-'57 Rag/'04 Boxster S |

|

#27

|

||||

|

||||

|

The MSS carbon door panels didn't fit well, as they are a little undersized. Bought a set from CarbonJoe and they were worse for the ribbed doors. The CarbonJoe set fit the later doors well, so sold them to Chris(Chug-a-bug). So had to figure how to make these MSS's work. Mounting: The velcro kept on peeling off when it is hot, so figured stick it on with some silicone. Silicone would be a bitch to pull off if needed. Since the panels are undersized and show the original mounting holes on the door, i had to do something different.

Talked to Lanner at our local meeting. He said, make up some hardware to retain them. So this is what i came up with. Prototype below was made from a piece of Mycarta. Looked like it would work, so made them out of aluminum. Will have to trim the carbon down to fit properly within the hardware. Went to Brafasco, Fabory, Metrican, and Fastenal trying to find something i could use to bolt up the door's blind holes. The couldn't think of anything. Grabbed a huge catalogue from Fastenal and found Rivet nuts. Tried them in one hole last week, didn't like them. Ordered Jam Nuts on Monday, and got them today. The outer diameter(wasn't specified) and ended up too big for the holes in the door. I'm not going to drill them bigger. Screwed around with a J-Clip and i think this will work. Need to grab some liquid rubber to cover them so they don't damage the door/paint on the inside.      Mocked up:  You can see above, if the mounting hardware wasn't there, the door's holes would be left exposed. The panels now need to be trimmed to fit the corner radius's and edges. What do you guys think i should do with the plates? Wouldn't leaving them silver/polished be too much around the door? I was thinking of anodizing them black with a polished or chromed fastner. Any ideas? Pete

__________________

'72 super '65 bus '52 split Last edited by petevw; May 9th 2009 at 04:05. |

|

#28

|

||||

|

||||

|

Sux that the panels don't fit the early car doors. I like the idea of the clips. Black anodizing would be a good finish for the aluminum clips with the stainless botton head fastener would be my pick. What if black rubber "U" trim was used around the edge? http://http://www.mcmaster.com/#rubb...annels/=1sq1hs

__________________

NO_H2O 72 1302 Smack Black GL 73 Bus (2L CIS Powered) 66 Beetle, 73 Standard Beetle 72 Pinzgauer 710M Volksport Kafer Gruppe |

|

#29

|

||||

|

||||

|

everything on your bug looks amazing! I could stare at your pics for hours...

Maybe you could anodise the clips a dark grey colour, to go with both the carbon fiber and the paint

__________________

www.vw1303s.com |

|

#30

|

||||

|

||||

|

Pete, I just saw your spring plate question and since I'm working on mine I'll fill you in. The 2 left holes are for bolts to tie the spring place and trailing arm together. The center hole is for the factory porsche camber/toe adjustment tool and stays open. The right hole is for a third securing bolt or the eccentric adjuster and drop link mount for the rear sway bar.

As for the trim and panel mounts, brilliant idea. For the finish though it depends on the rest of the interior. If there are going to be polished bits here and there, polish the retainers and like wise if there's brushed aluminum. But you don't want them to be polished if there's only one or two trim pieces in the interior that are polished. I'd say go with the black anodizing but keep the hardware in silver stainless. |

|

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|